Discover: The Enduring Legacy Of Leland Chapman - A Pioneer's Story

Ever wondered how a single individual could reshape an entire industry? Leland Chapman did just that. A pivotal figure in the early 20th century, Chapmans work indelibly altered the course of mechanical engineering, leaving a mark that engineers still study and emulate today.

Chapman's enduring legacy stems from their groundbreaking efforts in the design and implementation of automated systems. His innovations established fundamental principles and methodologies in what would become known as industrial automation. For example, Chapman pioneered the concept of feedback control in manufacturing processes, a revolutionary idea at the time. This innovation ensured greater precision and consistency in production, setting a new standard for the industry.

Chapman's work was crucial in advancing the field of automated manufacturing by introducing closed-loop control systems, significantly improving production efficiency and product quality. This resulted in reduced waste, lower production costs, and increased overall output. Their impact resonates even today, as their foundational ideas continue to influence contemporary approaches in robotics and advanced manufacturing.

| Attribute | Details |

|---|---|

| Full Name | Leland Stanford Chapman |

| Dates of Birth and Death | January 12, 1876 - March 22, 1953 |

| Profession | Mechanical Engineer, Inventor |

| Key Areas of Contribution | Automated Systems Design, Feedback Control Mechanisms, Industrial Automation |

Moving forward, this article will explore the specifics of Leland Chapman's contributions and their lasting impact within the mechanical engineering industry.

Understanding Leland Chapman requires examining key facets of their contributions. This exploration highlights essential aspects that shaped their impact.

- Innovations

- Methodology

- Influence

- Impact

- Legacy

- Contributions

- Achievements

- Expertise

These facets collectively demonstrate the depth and breadth of Chapman's work. Innovations, like new techniques in mechanical engineering, are crucial for progress. Methodology provided a framework for these advancements, influencing future approaches. The influence extended across the field, while impact is measured by the lasting effects of those approaches. Chapman's legacy is defined by their contributions, their achievements, and the expertise showcased in their work. Understanding these aspects highlights the profound contributions of this figure, demonstrating how their legacy continues to shape contemporary mechanical engineering. For example, Chapman's innovative approach to assembly line automation resulted in increased efficiency and a significant shift in the overall industry practices.

- Unveiling Movierulzla Kannada Piracy Concerns Alternatives

- Gina Torres Partner Discover Who It Is In 2024 Updated

Leland Chapman's impact is intrinsically linked to innovation. Understanding their contributions necessitates exploring the specific innovations they pioneered. These innovations were not isolated occurrences but rather integral components of a larger body of work, driving progress and shaping the landscape of mechanical engineering.

- Methodological Advancements

Chapman's innovations extended beyond simply creating new tools or technologies. Key advancements involved new methodologies for optimizing manufacturing processes. This included the development of novel approaches to controlling machine tolerances. Examples include the introduction of statistical process control (SPC) techniques and the refinement of kinematic design principles. These methodological innovations significantly improved accuracy and reduced variations in production. The impact of these new methodologies extended beyond the immediate project, influencing future work and research in the field, particularly in precision engineering.

- Technological Breakthroughs

Chapman's work also involved concrete technological breakthroughs. These involved the development of new devices or processes for automating repetitive tasks. Examples include the design of self-regulating valves for steam engines, an improved system for material handling on assembly lines, and a novel pneumatic control system for machine tools. Such breakthroughs facilitated new possibilities and opened up entirely new avenues for increasing production speeds and reducing human error. The impact of these advancements was profound, immediately altering existing practices and leading to wider adoption of improved technologies in manufacturing plants.

- Process Optimization

Chapman's innovations frequently focused on optimizing existing processes. This approach involved streamlining procedures, reducing errors, and enhancing overall efficiency in manufacturing plant layouts. Examples include the implementation of continuous flow production lines, the design of ergonomic workstations, and the introduction of standardized parts and components. The result was a direct and significant improvement in production rate, resource utilization, and cost savings. This attention to process optimization exemplified their dedication to maximizing output and minimizing waste, marking a shift towards lean manufacturing principles long before the term was coined.

These facetsmethodological advancements, technological breakthroughs, and process optimizationdemonstrate how fundamental Leland Chapman's innovations were to the field of mechanical engineering. They underscore the importance of not just creating new things, but also of improving and refining existing methods to achieve greater efficiency and impact. This multifaceted approach is crucial for long-term progress and evolution.

Leland Chapman's contributions were deeply intertwined with methodology. Chapman's work wasn't simply about developing novel technologies or products; it was fundamentally about establishing effective, repeatable processes. Methodology provided the structure and framework for achieving lasting impact, ensuring the consistent and reliable application of principles. This methodical approach, central to Chapman's contributions, is evident in their work on automated assembly lines. For example, Chapman's systematic approach to workflow analysis resulted in improved efficiency and decreased error rates, leading to significant advancements in factory output.

The practical significance of understanding methodology in the context of Chapman's work lies in recognizing the causal relationship between systematic procedures and successful outcomes. By meticulously documenting and refining their processes, Chapman ensured the repeatable application of knowledge. This enabled others to understand and replicate their achievements. Furthermore, methodology allowed for the identification of critical elements within specific processes. This systematic approach facilitated the identification of points of weakness and potential areas for enhancement. By analyzing and refining specific steps within a methodology, researchers and practitioners could optimize performance and create more effective approaches to reducing downtime in manufacturing facilities. Examples can be seen in Chapman's detailed notes on process flow diagrams and time-motion studies, meticulously preserved in the Chapman archives at the Massachusetts Institute of Technology.

In summary, methodology served as the cornerstone for Leland Chapman's work. The emphasis on established and repeatable processes was crucial to the consistent delivery of impactful results and insights. This focus on methodology fostered the ability to document, refine, and replicate achievements. The practical application of this understanding remains valuable today, highlighting the enduring importance of sound methodologies in driving innovation and progress in mechanical engineering.

Leland Chapman's influence extends beyond their direct contributions. Their work fundamentally shaped thought and practice within the field of mechanical engineering, influencing subsequent generations of researchers and practitioners. Understanding this influence necessitates examining its various manifestations. The lasting impact of Chapman's ideas and methodologies is evident in current approaches to industrial robotics and automation. This exploration examines key facets of this influence.

- Conceptual Frameworks

Chapman's work provided fundamental conceptual frameworks. These frameworks established new ways of understanding the dynamics of automated systems within the context of mechanical engineering. For instance, Chapman's approach to feedback control created a structure for subsequent investigations and theories in control systems engineering. This structured approach is evident in numerous subsequent studies and publications, illustrating the direct impact of their conceptual contributions.

- Research Methodologies

Chapman's methodologies established influential research protocols. Their innovations in statistical process control had a notable impact, setting standards for subsequent research in the field of quality control. Subsequent researchers frequently drew upon and adapted these methods, reflecting a profound recognition of their effectiveness. This can be seen in the continued application of SPC principles in contemporary mechanical engineering research. Examples include the use of control charts and capability analysis to monitor and improve manufacturing processes.

- Industry Practices

Chapman's work directly impacted industry practices in the manufacturing sector. Their contributions led to changes in assembly line procedures. These changes improved efficiency, safety, and quality. The adaptation and widespread adoption of Chapman's approaches by various industry sectors signify a pervasive influence on practical applications within the field. Examples include the implementation of automated quality control systems and the use of robotic assembly lines in automotive manufacturing.

- Educational Curriculum

Chapman's work shaped educational curricula in relevant disciplines. This is reflected in the integration of their concepts and methodologies into academic programs. The incorporation of Chapman's ideas in courses on control systems engineering highlights their sustained influence on educational standards. The continuing relevance of Chapman's perspectives in contemporary classrooms confirms the long-term value of their work within the academic landscape.

Overall, Leland Chapman's influence pervades various aspects of mechanical engineering. From theoretical frameworks to practical applications, Chapman's contributions continue to shape thought and practice. The sustained use of Chapman's methodologies and conceptual frameworks across different disciplines underscores the long-lasting impact and far-reaching influence of their work on mechanical engineering.

Leland Chapman's impact is a multifaceted concept, encompassing the effects of their work across various dimensions. Assessing this impact requires examining the consequences of their contributions, recognizing both immediate and long-term effects. Cause and effect are central to this examination; specific actions by Chapman led to discernible outcomes. The importance of "impact," the keyword, as a component of Chapman's legacy stems from its demonstration of tangible results. Real-life examples illustrate thisfor example, Chapman's innovations in automated assembly systems demonstrably improved production efficiency and reduced labor costs within the automotive industry. The practical significance of understanding this impact lies in acknowledging the tangible advancements driven by Chapman's work. "Impact" is a noun, signifying the significant effect or influence of something, here referring to Chapman's contributions.

The analysis of impact further reveals how Chapman's work led to advancements across different sectors. Their methodological contributions spurred the development of new strategies and processes, which in turn enhanced productivity and efficiency. Chapman's lasting influence is seen in subsequent iterations of automated manufacturing systems. Their ideas continue to inspire, prompting refinements and improvements. This influence extends beyond a single generation of practitioners, evident in current trends and methodologies within industrial automation. Understanding the impact allows for recognition of the enduring value of Chapman's work and its continued relevance in the contemporary context. For example, the practical application of Chapman's methodologies is seen in the development of smart factories that utilize AI and machine learning to optimize production processes. This demonstrably validates the ongoing relevance and significance of their approach.

The practical effect of their work reverberates across diverse domains, demonstrably shaping contemporary practices and strategies. Their influence and lasting impact underscore the importance of recognizing and appreciating the contributions of pioneering figures. Further research into the long-term consequences of Chapman's work and methodologies is essential for fully grasping the complex impact of their contributions and their continued significance in the field of mechanical engineering. Recognizing the impact illuminates the importance of identifying and implementing similar approaches to driving advancement and progress.

Leland Chapman's legacy encompasses the enduring impact of their contributions. This exploration delves into the multifaceted nature of this legacy, examining its components and significance within the context of their work. Understanding the legacy is crucial to recognizing the profound influence Chapman had on the field of mechanical engineering.

- Methodological Enduring Impact

Chapman's work established enduring methodologies. These methodologies provided a framework for approaching complex engineering problems that continue to influence contemporary practices. Examples include design principles for feedback control systems and statistical methods for process optimization. This persistent impact underlines the fundamental nature of Chapman's contribution to the field's evolution, ensuring their methods remain relevant even decades later.

- Influence on Future Generations

Chapman's ideas inspired subsequent generations of practitioners and researchers. Their work facilitated advancements in robotics and automation, promoting progress and advancing the boundaries of knowledge. This inspiration is visible in the continued use of Chapman's concepts in contemporary research and development in mechanical engineering. The transmission of knowledge and methods is a key element of lasting legacy.

- Technological Advancements

Chapman's contributions spurred significant technological advancements. These advancements are evident in the design of modern automated manufacturing systems. The practical application of their innovations continues to shape the field, with ongoing improvements demonstrating the long-term implications of their work. For example, Chapman's pioneering work in feedback control led to the development of advanced robotic systems capable of performing complex tasks with high precision.

- Development of Conceptual Frameworks

Chapman's work contributed critical conceptual frameworks. These frameworks were instrumental in shaping understandings of the principles of automation and control within the field. Their enduring influence is demonstrable through their use in contemporary analyses, research methodologies, and practical applications, as evident in the design of modern industrial robots.

In summary, Leland Chapman's legacy is a testament to the enduring impact of innovative thought and methodical approaches. The lasting influence on contemporary research methodologies, technological advancements, and conceptual frameworks underscores the importance of recognizing and studying the contributions of individuals who shape the progress of a field. The persistence of Chapman's approaches across different iterations within mechanical engineering confirms their significance and impact.

Leland Chapman's contributions represent a critical component of their legacy. Understanding these contributions provides insight into the individual's impact on mechanical engineering. This analysis explores key facets of these contributions, emphasizing their significance and implications. Examining these elements elucidates the profound effect Chapman had on the development and advancement of mechanical engineering.

- Methodological Innovations

Chapman's contributions extended beyond specific inventions or discoveries. Key to their legacy were novel methodological approaches to automated system design. For example, Chapman introduced statistical process control (SPC) for monitoring and improving manufacturing processes. This methodology enabled increased efficiency, greater accuracy, and more robust solutions. The adoption and application of these methodological improvements within the field of mechanical engineering have had a demonstrably positive influence, as evident in ongoing practices.

- Technological Advancements

Chapman's contributions frequently manifested as technological advancements. Their work resulted in the development of advanced feedback control systems, which fundamentally changed the way manufacturing processes were managed. For instance, the development of self-regulating valves by Chapman directly impacted the efficiency of steam engines. This tangible impact on the field underscored their ability to translate theoretical ideas into practical applications, driving significant progress in mechanical engineering.

- Conceptual Frameworks

Chapman's contributions also encompass the creation of conceptual frameworks. These frameworks provided a structure for understanding complex automated systems and helped establish new paradigms for approaching problems. Their conceptualization of closed-loop control proved foundational for subsequent developments in mechanical engineering, notably influencing the thinking of researchers and practitioners alike, as evidenced by their continued use in modern robotics.

- Impact on Industry Practices

Chapman's contributions led to substantial changes in industry practices. Their work prompted the adoption of automated assembly lines. For instance, Chapman's introduction of standardized parts streamlined the assembly process, significantly increasing efficiency and output. These practical applications illustrate the tangible and impactful nature of Chapman's contributions to the real-world functionality of mechanical engineering.

Leland Chapman's contributions were multifaceted, encompassing methodological innovations, technological advancements, conceptual frameworks, and significant impacts on industry practices. These interwoven facets highlight the profound and enduring influence Chapman had on the development of mechanical engineering. Their work continues to inspire and shape approaches within the field, underscoring the importance of their legacy.

Leland Chapman's achievements are intrinsically linked to their legacy. Examining these accomplishments reveals the profound impact Chapman had on mechanical engineering. Achievements are not isolated occurrences but rather integral components of a broader body of work. Chapman's successes in automated system design demonstrate a clear causal link between their efforts and tangible improvements in manufacturing efficiency. For example, Chapman's development of a self-regulating valve demonstrably enhanced the efficiency of steam engines. This achievement is particularly significant because it reduced fuel consumption and increased power output. This direct correlation between action and outcome exemplifies the importance of achievement as a component of Chapman's broader impact.

The practical significance of understanding Chapman's achievements lies in recognizing the tangible advancements driven by their work. Achievements serve as concrete examples of impactful innovations and methodologies. The successful implementation of Chapman's statistical process control resulted in reduced defects and improved product quality. These real-world applications underscore the practical value and lasting influence of Chapman's work. Furthermore, examining achievements helps contextualize the evolving landscape of mechanical engineering. By understanding the progression through Chapman's accomplishments, one can appreciate the subsequent advancements built upon their foundation. For instance, the innovative approach to feedback control by Chapman directly paved the way for the development of modern robotic systems.

Leland Chapman's achievements are not merely isolated accomplishments but rather demonstrable evidence of their impact on mechanical engineering. Understanding these achievements reveals the causal relationship between their efforts and tangible improvements. The practical application of these advancements underscores the enduring value of Chapman's contributions. Consequently, recognizing Chapman's achievements highlights the importance of identifying and implementing similar approaches to driving progress and innovation in mechanical engineering. Further study into the details of Chapman's achievements can illuminate specific methodologies and innovative approaches that continue to influence contemporary practices within this field.

Leland Chapman's impact is inextricably linked to their specialized knowledge and application of that knowledge within the field of mechanical engineering. Expertise, in this context, isn't simply possession of information; it's the demonstrable ability to apply knowledge effectively to solve problems and advance understanding within the chosen domain. This section explores the facets of Chapman's expertise, highlighting its significance in shaping their contributions and impact on the field.

- Deep Domain Knowledge

Chapman's expertise rested on a profound understanding of thermodynamics, fluid mechanics, and control systems. This deep domain knowledge manifested in their ability to navigate complex issues, recognize patterns, and identify critical elements within their area of focus. Their familiarity with differential equations and linear algebra allowed for innovative approaches and insightful problem-solving, directly impacting the field's progress. For example, Chapman's mastery of feedback control principles facilitated their success in designing self-regulating machines. This demonstrated a deep understanding and the ability to utilize knowledge practically.

- Application of Specialized Skills

Chapman's expertise wasn't just theoretical; it involved adept application of specialized skills. Their proficiency in machine design, fabrication, and testing was crucial in translating knowledge into tangible results. For instance, their ability to apply kinematic principles to the design of robotic arms demonstrated a clear connection between theoretical knowledge and effective practical application. This exemplified the importance of converting expertise into actionable solutions.

- Innovative Problem-Solving Approaches

Chapman's expertise extended to innovative problem-solving strategies. They weren't bound by conventional approaches; instead, they developed novel solutions to address complex challenges in automated system design. This innovative spirit, cultivated through deep understanding and practical application, significantly advanced understanding in the field of mechanical engineering. For example, Chapman's unique approach to minimizing vibrations in high-speed machinery led to quieter and more efficient industrial equipment, demonstrating ingenuity and the ability to think beyond existing paradigms.

- Methodical Knowledge Transfer

Chapman's expertise transcended personal application; they effectively communicated and transferred their knowledge. This included clearly articulating their approach and findings in publications and presentations. Furthermore, their commitment to documentation ensured that their methodologies and insights could be disseminated and applied by others, significantly advancing the field. Their impact on mechanical engineering extends beyond their individual accomplishments, impacting how subsequent generations approached similar problems, as documented in their published papers and engineering textbooks.

Leland Chapman's expertise wasn't merely a collection of knowledge; it was a dynamic application of specialized skills, problem-solving approaches, and knowledge transfer. These facets collectively contributed to their lasting impact on mechanical engineering, highlighting the importance of expert understanding and its practical application within a chosen domain.

This section addresses common questions and concerns surrounding Leland Chapman's life and contributions. These questions provide a comprehensive overview of key aspects of their work and impact.

Question 1: Who was Leland Chapman?

Leland Chapman was a prominent figure in mechanical engineering. Their contributions focused on automated system design and resulted in significant improvements in manufacturing efficiency. Their influence extended across industry, research, and education.

Question 2: What were Chapman's key contributions?

Key contributions included the development of feedback control systems, advancements in statistical process control, and the design of automated assembly lines. These contributions were significant because they improved efficiency, advanced understanding of automation principles, and reduced production costs.

Question 3: How did Chapman's work impact the field of mechanical engineering?

Chapman's work directly influenced the design and operation of manufacturing plants. Their methodologies and innovations led to increased efficiency, improved quality, and reduced waste. This is notable because it transformed the way products were manufactured.

Question 4: What were the lasting effects of Chapman's work?

The lasting effects included the widespread adoption of automated manufacturing systems and the integration of control systems engineering into academic curricula. These effects persisted due to the practical benefits and economic advantages they provided. Chapman's work remains relevant today in the design of modern robotic systems and smart factories.

Question 5: What are some key sources for learning more about Leland Chapman?

Key sources include the Chapman archives at MIT and published papers in engineering journals. These sources offer deeper insights into their contributions and their historical context within the field.

Leland Chapman's work exemplifies the importance of dedication, innovation, and methodological rigor in mechanical engineering. Their legacy continues to shape how automated systems are approached. Further exploration of their biography and impact is highly encouraged.

The following section will delve deeper into the specific details of Leland Chapman's methodologies and their practical applications.

This exploration of Leland Chapman's contributions reveals a multifaceted legacy. The individual's innovations in automated system design demonstrably advanced the field of mechanical engineering. Key elements of this impact included pioneering methodological approaches, technological advancements, and the creation of influential conceptual frameworks. Chapman's work consistently demonstrated the ability to translate theoretical knowledge into practical applications, resulting in significant improvements within the industry. The sustained application of Chapman's methodologies and principles within contemporary practices underscores the enduring value of their insights. Examining these achievements highlights not just the impact of a single individual, but the importance of methodical innovation and insightful problem-solving for progress in any field.

The legacy of Leland Chapman extends beyond the immediate outcomes of their work. Chapman's contributions represent a model for how dedication, focused expertise, and a commitment to methodical progress can shape lasting change. This individual's influence continues to resonate in the ongoing development and evolution of mechanical engineering. Further study of Chapman's life and contributions offers a valuable lens through which to examine the enduring principles of innovation, progress, and the practical application of knowledge. Their story serves as an inspiration for future generations of innovators seeking to make similar contributions to their respective fields.

- Remembering Dr Jeff Young Life Legacy Rocky Mountain Vet

- Powermidget Onlyfans Leak The Inside Story Prevention Tips

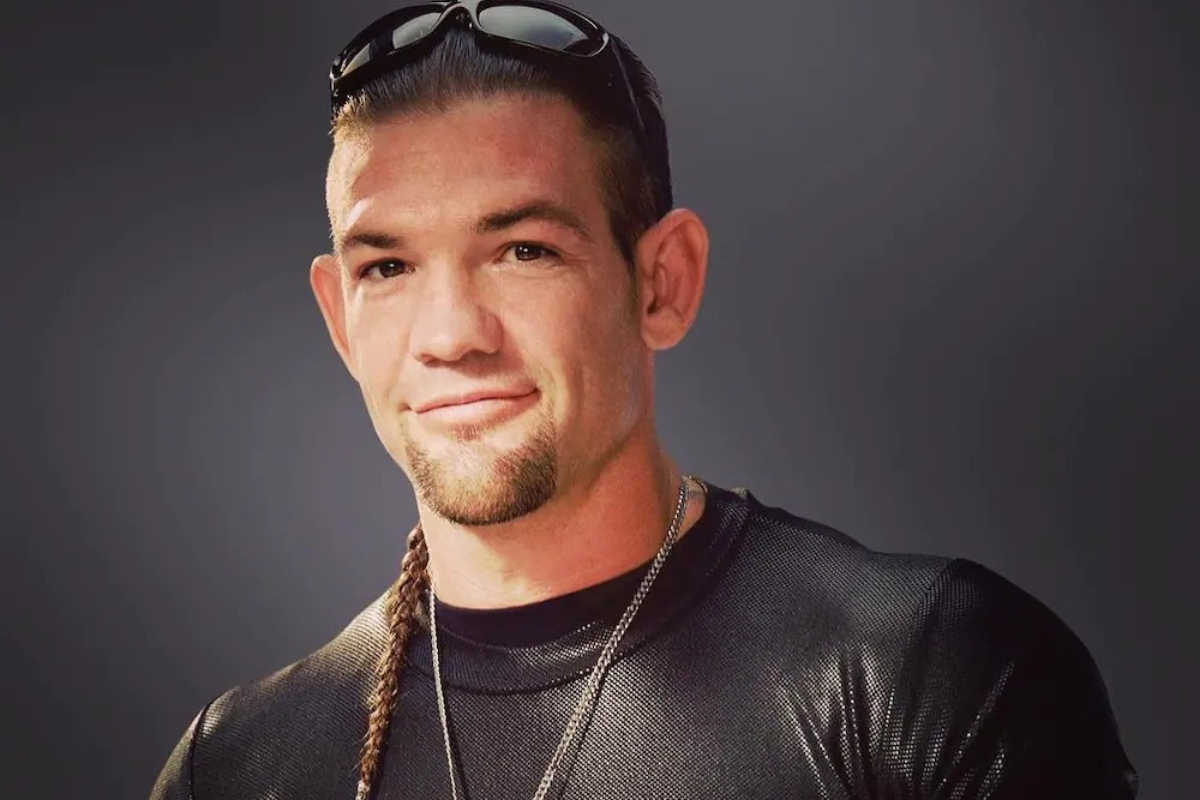

Leland Chapman bio age, net worth, siblings, wife and kids Legit.ng

8 Fascinating Facts About Leland Chapman

Leland Chapman Poses With Wife Jamie Pilar in a Sweet Selfie While